Industry Projects WaterstofNet

Industry Projects WaterstofNet

Worldwide there is a demand of 70 million tons for hydrogen as a raw material for the industry, mainly the (petro) chemical industry, but also food, steel, electronics, .... In Belgium this is about 600 kilotons (kton) or 600,000 tons of industrial hydrogen. The demand for this hydrogen is still mostly filled by fossil fuels, mainly through the cracking of natural gas (SMR). This process causes significant CO2 emissions.

Making these enormous quantities of fossil hydrogen sustainable through the use of low-carbon hydrogen (such as residual hydrogen or hydrogen from SMR where the CO2 is captured and stored and / or reused) and green hydrogen from electrolysis is an important challenge, for which no other sustainable alternatives exist.

In addition, new applications are also possible within industrial processes for hydrogen. We are thinking of the steel industry with a partial replacement of cokes by sustainable hydrogen in the blast furnace process or even a completely new process with hydrogen at the base, in which direct-reduced iron (DRI) is produced by directly reducing iron ore with a reducing gas.

Hydrogen will form the basis of sustainable chemistry around which new applications can develop, such as synthetic fuels, also known as e-fuels. Here CO2, which is captured in a combustion process or in the future even from the atmosphere (direct air capture) and then reused (carbon capture and utilization – CCU), is combined with sustainable hydrogen to form a liquid fuel.

Within industry, hydrogen can also meet certain electricity and heat demands. Via the power-to-power principle, hydrogen can supply electricity via stationary applications, for example as a generator or back-up, or it can offer storage options for locally generated (surplus) green energy. Heat demands can also be met by means of combustion or via fuel cells. We are thinking in particular of high temperature processes that are difficult to electrify.

Linking Hydrogen Power Potentials in the North Sea Region

Contributing to the creation of an integrated hydrogen market within Netherlands-Belgium-Luxembourg-Germany-France

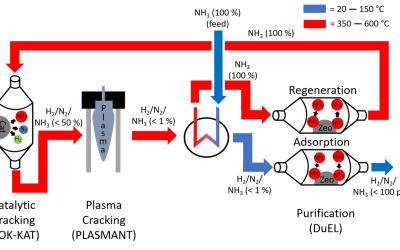

Research into an efficient process for cracking green ammonia into hydrogen

Study on the large-scale import of hydrogen from other continents

Large-scale hydrogen production in a port environment

Promoting and providing H2, transformation and low carbon infrastructure in the EMR Region

Offshore wind and green hydrogen in the North Sea Region

Wind energy, hydrogen, forklifts and smart grid

1 MW fuel cell plant on residual hydrogen