Dutch VSPARTICLE and Plug Power demonstrate breakthrough technology to drastically reduce the Iridium utilisation in PEM electrolysers

An important advantage of PEM electrolysers is their ability to respond dynamically to intermittent renewable energy. However, their reliance on iridium, one of the rarest platinum group metals (PGMs) is considered to be a major barrier for scaling up. Traditional catalyst coating methods are inefficient, often requiring 1-2 mg/cm² of iridium.

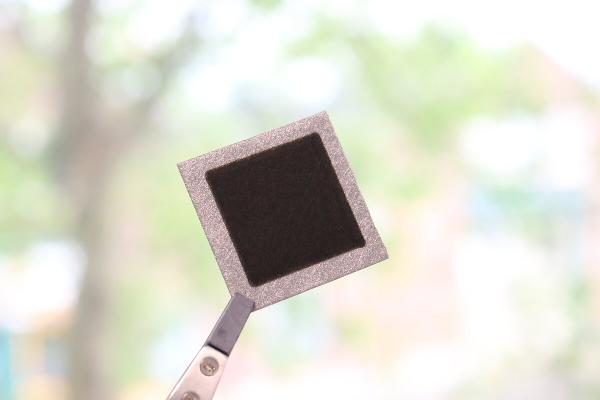

VSPARTICLE's technology addresses this issue by creating a highly uniform, nanoporous structure without PFAS-based ionomers or solvents. This nanoporous layer technology, that maximizes the electrochemical surface area (ECSA) of the precious metal, can realise a 10x improvement in iridium utilization thus enabling an important cost reduction.

The collaborative project with Plug Power Inc. and the Center for Clean Hydrogen, directed by Professor Yushan Yan at the University of Delaware, achieved outstanding performance while using up to 90% less Iridium.

VSPARTICLE is scaling its in-house coating capacity to support pilot and early commercial projects with multiple top-tier PEM electrolyzer manufacturers. Commercial-scale testing programs are planned to start in 2026.

More info can be found here.